I avoided caulking around the downhill sides of the storm-door frame and trim next to it, though, so any water inside could drain out to the front. Same principle as not sealing the lower flange of a window.

| With roof completion on hold and no immediate scheduling for the remaining parts of the project, I had a little more downtime to usefully fill from my own to-do list. The hutch could wait until after one item with a slightly higher priority was handled. With the roofers no longer scrambling up and down the house I could get back to dealing with the splash issues at the front door, before anything bad started to happen around there. |

Water management revisited

[Click any image for a larger version.]

|

I had already bought a "zip tool" and read various references on how to

use it, as it's clearly something that every owner of vinyl siding needs

to have. I ran across a

great article

on the topic that has far better pictures and explanation than I could have

put together, and seems to even show the same siding color. The tool is

really fun -- it's like a lockpick for siding. While not perfectly

adapted to all types of interlock shapes it does pretty well; the key to

success is to work it in at the *end* of a piece and then start running

it along. Trying to grab and open a piece midway along just plain

doesn't work.

So here the guys had worked so hard to rebuild my walls and get everything all neatly buttoned up, and here I was starting to rip it apart again. |

|

The house got me back, though -- it ate my head. |

|

In the meantime a generous batch of replacement weep-hole inserts for the windows had arrived from Serious, so I went around and filled in all the missing ones. |

Gimme shelter

Refrigerant rework

|

With exterior issues on the HVAC unit taken care of, it was time to think

about its internal issues as well. After the somewhat botched install and

startup it had been working okay over the summer, but I still wanted a

second opinion and possible rework. After a bit of delay and failure to

communicate I finally managed to schedule an appointment with

N.E.T.R., a local company that

had been recommended by the Daikin application-engineering folks. They

seemed understanding about my saga to date and not afraid of a homeowner

with a clue, and said they'd put their "A" Daikin tech on the job. He's

obviously a busy guy in high demand, and had also recently hauled all

the way out to west bumfuk to have a look at a friend's systems at his

cohousing site so we'd have

an opportunity to compare notes.

This was going to set me back an additional bit of coin, but well worth having my system in a known state of repair. The day for the checkup held a significant threat of rain later on, but there seemed to be enough time to do this in the morning. Just in case, I moved my canopy over the area in front of the unit to keep things drier in case it started spitting during non-interruptible operations but was careful to not place it too far in, as its wrong-sloping cover would shoot water *toward* the wall. |

|

The guy arrived and I toured him through the system and the massive nordic saga behind it, and we agreed that pulling the old charge and doing all the proper pressure and vacuum tests before replacing it was the most sensible path to take. He got his recovery rig out of the van and hooked it up, put the system into the special "vacuuming" mode that opens all the valves, and extracted slightly under six pounds of refrigerant into the bottle. |

|

A recovery machine is basically just a compressor that can handle both

liquid and vapor, and move same from one place to another. It will bring a

system to slightly negative gauge pressure but it is not a real vacuum pump.

Recovered refrigerant, even the more environmentally-benign R410A, has to have a paper trail. The recovery bottle is a one-shot thing per job and never got taken out of the box, and he had to write what was inside it and how much [from the electronic scale underneath] and even where the contents came from on the outside for when he took it to the collection facility. In theory, it all gets recycled and purified back into usable new refrigerant. I assured him that the hutch and front posts could be disassembled and removed in a few minutes if he needed, but he seemed to have plenty of working room around the service valves with the post in place. Enough to put a couple of wrenches on the flare joints to check them, too. I had a vague notion we should open the flares for another check and maybe Nylog them, but his experimental pull on the big one let him know that it was *very* tight now and the better part of valor, in the interest of just not messing it up any further, might be to simply leave it as it was. I agreed, especially as we hadn't really tested it yet. | |

|

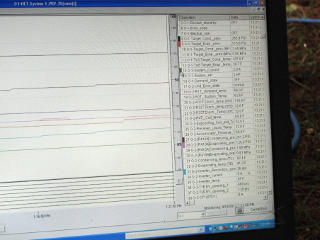

The Checker had a concept of where various running parameters should be

in the given conditions, and the live system readings came nicely right up

to those targets as it stabilized. The tech was happy about that, and

declared things to be in excellent shape now.

He possibly ran these tests a little longer than needed, but Service Checker is actually *dog-slow* about collecting its figures and he wanted to make sure we had good readings. Along with confidence that the system was now set up right, the fun HVAC geek-fest that he and I wound up having over this whole process was absolutely worth every penny I was paying for this visit. He said he'd mail me the data log file that the Checker had generated in the process, and did so after getting back to the office. |

| At one point he mentioned the existence of an "inverter checker" tool, which I might have run across a brief cryptic reference to in one of the manuals but no real details on. He didn't have one on hand, however. I found a few more hints about it online later and it seems to be a simple box that plugs into the compressor motor leads and lets the inverter output light some LEDs instead of spin the motor. In fact, it's likely very similar to the three-phase display we came up with to show the output of a Prius motor/generator, shown near the beginning of this tech-training summary. Bidirectional two-color LEDs are ideally suited for this sort of thing, so if I ever need an inverter-checker for this thing I know exactly what to put together. | |

... And a wet Dow(g)

Foam fun with Foam Run

|

During the roofing I had gotten a visit from the spray-foam contractor,

and we toured around the basement so he understood what needed to be

done. I still had a bit more clearing away from the perimeter to finish,

but he was pretty happy with the access I'd already created. Eventually

we got a day scheduled to do the job, and I would make sure to be about as

ready as I could for when they came in.

We had also finally resolved the whole closed-cell vs. open-cell foam quandary, as the Synergy folks had gotten some clarification while they were out at Joe's summercamp-slash-love-fest in Westford. They learned that moisture can not only migrate through wood, it can migrate across a junction of two pieces of wood touching each other and thus enter or leave a piece of wood that appears otherwise isolated in a structure. In addition, the concrete block that my sill is in contact with is relatively permeable including out toward the exterior above-grade surface which was going to remain uncovered by any kind of vapor barrier, so basically between the joists resting on the sill above and the block wall below the rest of the visible sill could safely be entombed in low-permeance closed-cell foam and still have ample drying opportunity. With my sill relatively high above grade in the first place we agreed that very little moisture was likely to capillary its way up through the wall that far, especially when the soil near the wall was going to remain far less wet under the new roof than it had previously. The moss growth patterns in various areas would tend to support the theory. [Compare with many houses where the mudsill is almost literally *in* the mud with mere inches of exposed foundation.] So closed-cell foam was clearly the way to go. Besides, I had more evidence right in front of me that moisture really just isn't a problem with this foundation in general. |

|

They shot a test patch onto some plastic to make sure the mix was right, and were then ready to start. |

|

Finally he worked past the tight part, and the rest would be pretty smooth sailing along the sill area. They were foaming all the way around the foundation notches for windows and ex-window blockoffs, because that's where the 45-degree masonry parging continued from the sill and was a source of many air leaks. The whole idea here was to get a continuous air seal around the sill and related areas more than trying to add actual R-value, and connecting between the top of each bay down to the block wall and onto the top of the old styrofoam would cover all the known leaky bits along there. |

|

I could see that these foam guns are not very forgiving tools, since they're

designed to apply large volumes of this stuff at high speed in big

buildings and here were only applying one delicate little strip of the

stuff. The guy had to take *tiny* little shots, and it's rather impressive

how quickly the foam expands after hitting a surface. I

shot a little video

of this. The steady hissing is from the compressed air, and the gun

trigger valves in the foam components so they mix and then get shot

out the nozzle as a fine but powerful spray. Not something you want

your skin in the way of for a bunch of reasons.

Not only is the foam already warm, but the curing process is exothermic. Fairly high heat can develop inside applied layers, and the better foam installers know to go in very thin layers and give it generous expansion and cooling time before adding more. Extreme cases of foam applied too fast and heavy have actually started fires. The guys were joking about one of their co-workers who wasn't on this job, who they said would have been "done already" when they were about halfway around. But that would have been at the expense of sloppy and hasty application, as apparently that fellow tries to shoot way more on per pass than he should. Hopefully they'll be able to talk some sense into him down the road. | |

|

As I had been out to

Carlsbad Caverns

the previous summer and came back with lots of pictures of stuff most

people never see because it's too dark, the appearance of the foam struck

me as rather similar to what I'd seen underground. This could only lead

to one conclusion ...

It's my Man Cave! |

|

This concluded the final component of the big retrofit, and now we were

just waiting on the backordered roof material. There was a lot more that

*could* have been done on the basement, and many case studies go into

extensive detail on jobs that pour a whole new insulated slab floating

in a foam "bathtub", put four inches of spray or rigid foam on the walls,

dig out the entire foundation wall and slap Roxul or something on the

exterior, etc etc. I decided early on that for my "not quite as deep

as some" retrofit I probably didn't need to go to such lengths, given that

the previous owner had added a nicely vapor-permeable R-5 layer of EPS

when it was trendy in the seventies and I totally didn't mind if the

basement generally ran a little cooler than

the rest of the house in winter. The main thing was to get rid of all

the air leaks, which my window/door reworks and now the sprayfoam had

handily done.

In the meantime, there were numerous followup things that would be up to me to deal with, as it was pretty clear that the main construction crew was done with whatever they were going to do. |

|

As a last-ditch effort I finally tried the "ReStore" at the local Habitat for Humanity, and they'd be delighted to accept it into their building-materials pool including all the miscellaneous cut-offs. Not sure what they could do with the relatively small quantity as far as actually using it as siding, but I wasn't going to argue. Arranging to take it to them made another fun shot for the Prius loads page. |

| It's actually been somewhat tempting to volunteer as build crew on some of the Habitat projects, as it might provide more learning experience. But they often get into some pretty nasty neighborhoods, so that along with the organization's religious ties gives it significantly less appeal. | |

_H* 121226