|

Over many of our objections, the town planning commission voted to approve

the upgrade plan basically because they'd get a paving job for free.

The developer wanted it done and would fund this piece even though

it lay in a different *town* from his subdivision -- as the only vehicle

access it would still pretty much make sense for the potential increase

in traffic. Thus we failed to use disapproval of this as a wedge to impede

the rather unpopular subdivision itself, but it was definitely thought of.

Long story short, we the peasants brought our pitchforks and torches

to a lot of planning hearings over the years, ultimately to no avail.

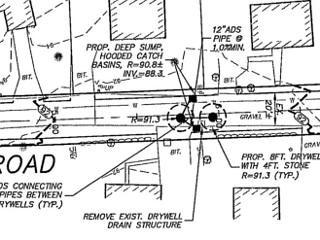

So it eventually came time to engineer the improvement, and our town

asked for a solid, durable design for it. Changing to an impermeable

surface would affect all the drainage characteristics, especially for

water flowing down the gentle hill, so stormwater management was key.

As the nearest land lower than the street was a wetland preserve that

already had zero drainage, they weren't going to send it there. The

only other choice was sufficient volume of deep soil infiltration to

basically just make all the water go away. Including the amount that

could be anticipated to come in the typical "hundred year event".

|