|

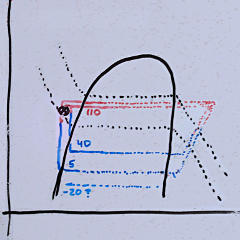

I could finally do some more "blower door" test runs, or more properly

"blower window" as

my depressurization rig was the box fan upstairs with some blocking

around it to contain airflow. It was plenty of pressure differential

to make cold air come howling in wherever it would and get spotted on

the IR. It was a reasonable suspicion that a year of temperature cycles

and settling could have opened up new gaps in the shell just about

anywhere! After some time of running it I found chilly spots in some

unexpected places -- in general it seemed like air could slowly diffuse

right through the foundation wall *and* the EPS styrofoam wherever

it was still exposed. But as I've learned it's not that surprising, when

you think about the

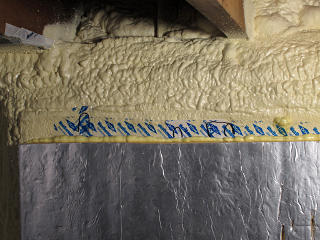

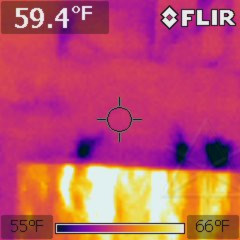

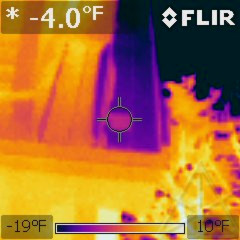

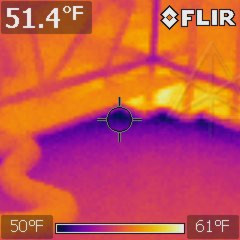

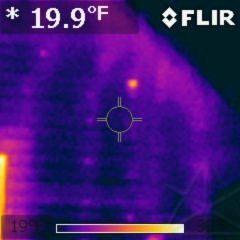

porosity of both substances. At one place in particular I had previously

slapped some tape along the old stuff above my new insulation layer thinking

that it would suffice to seal it up, and that turned out to be a bad

assumption. The two pictures are of the same area, and the issues

are obvious.

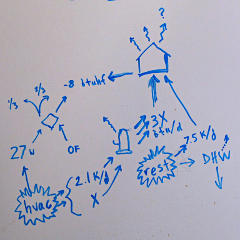

I wound up stripping off most of that tape and caulking deep into the little

butt-joint seams in the EPS that were bringing in most of the infiltration,

and then adding another layer of sprayfoam along the top of everything.

Where there weren't actually visible seams the remaining exposed EPS, as

little of which showed anymore, definitely became a bit colder during the

test which could only be from incoming exterior air working its

way in *somehow*.

It was easy to become rather obsessive about more air-sealing over the

course of that late fall,

as I still appeared to be fighting some remaining issues near the sill

pans at the front and side doors. The problem there was that leaks around

anything mounted in a rough opening can let air wander in and travel

just about anywhere through the framing structure to show up in unexpected

places. The root cause was basically unfixable now, but I could try to go

after the secondary effects. It was a bit of whack-a-mole for a while --

I'd stop one air leak and a couple of smaller ones would show up elsewhere

nearby where they weren't before. But steadily less so, and I was prepared

to hunt down as many accessible endpoints as necessary to minimize those

leakage paths. Ultimately dollops of sprayfoam got squirted into quite a

few little corners and joints around the new reinforcement framing under

the front door as it appeared to be needed and even some subfloor board

gaps at the edges. The IR imager gave greatly enhanced visibility into

all this, although the remaining cold spots I could find started being more

likely from conductive loss through wood or thinner spots in the sill-area

foam job than from actual air leaks.

For more perspective on all this and good examples of what may need to

get chased down in a typical home, watch

this video

from the folks at "Green Dream" in Chicagoland.

One thing to also keep in mind is that wood shrinks a little when it

gets dry and cold in the winter, which may affect how doors and

windows fit and close, and I needed to stick a few small bits of the

high-compression open-cell type foam strip here and there to augment

some of the door weatherstripping.

On the bright side,

the other recent changes seemed to have succeeded nicely.

The basement was generally much better sealed, and even that dubious

cut-n-cobble job in the storage shelf looked great, no cold spots at all

in there. I didn't see any problems around any of the "footing" for the

new polyiso so I'd apparently done a pretty good job

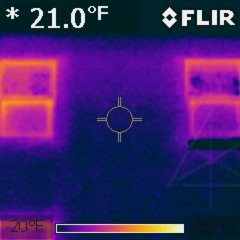

on sealing that up as it went in. Persistence paid off: overall the place

was definitely quite a bit tighter than when we had done the actual

post-reno blower door test -- probably pushing passivhaus level by now,

although I didn't have a way to actually measure that. Running the

depressurization for over an hour without the house notably cooling down

at all and only showing minor isolated and explainable cold areas was a

pretty good indication, though.

Back on autopilot

It was time to head off for another roadtrip for a while, and this time I

left the ventilation enabled on its minimum setting as the house started

to cool down just prior to leaving. This would ensure that the relative

humidity wouldn't climb too much as the interior drifted down to the

"setback" temp I'd set at 52F, which I definitely wouldn't be around

for. By the time I got on the road everything had pretty much equalized

at 57F and the basement slab was still slightly *warmer* than that, so it

would take quite a bit longer to reach setback against an ambient in

the mid-30s at the time. Winter

heat-pump strategy had become a single programmed event in the controller --

on weekdays, simply shut off at noon [e.g. go to the setback temp, the way

Daikin defines it], where it would remain unless I was home to actively

turn it back on after peak hours were over. So I didn't have to change

any of that before taking off.

I returned in a leisurely way in the early days of January, overnighting

at the home of a semi-distant relative in rural Pennsylvania right as

one of the winter's several big snowstorms arrived to blast the northeast.

The run up the backbone of Virginia had become progressively more, uh,

interesting that afternoon and it was nice to be able to get away from

the highway and its rapidly increasing collection of vehicles slid off the

road toward evening. As the storm passed over it got *wikkid* cold, down

to 0F or less by the morning when I helped her shovel out and began

my last leg for home.

Said relative had recently replaced a woodstove with a small propane-fired

stove that simply exhausts its burned gases into the living space. I

was mildly horrified, thinking there was no way these were code anymore,

although I know that unvented combustion heaters of all sorts are in

common use all over the world. With a source of clean fuel I guess they're

not all that hazardous but on coming into the house I could definitely

smell some combustion gases and the humidity in there was likely higher

than it should have been and landing its share of condensation on her

windows. I urged her to go buy a CO detector asap at the very least.

On the bright side this little burner, located at one end of the house,

was actually keeping the whole place warm by itself with no help other

than a small booster fan to push a little air down the hall. Her late

husband had put some good work into tightening and insulating the house,

and it appeared to be paying off.

That night's storm was the first or second in one of the coldest winters

on record for most parts of the country, which kept everyone pinnned under

the "icy polar-vortex finger of death" until well into April 2014. In

the meantime it dumped lots of snow and ice everywhere, paralyzed

the entirety of

Atlanta GA,

and probably boosted national oil and gas profits

beyond all expectations of corporate greed. The oversensationalized

"omg this one's going to be huge" reports from weather.com and such

became a commonplace weekly heartbeat, and at some point I think they

even gave up on their apparent imperative to name every storm that whisked

through because there were so many. Naturally I was like "bring it",

because it would enable a lot more testing and experimentation on

the house with a nice steep temperature delta going on.

|