|

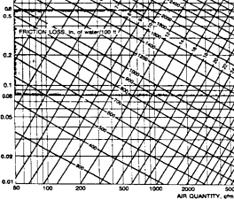

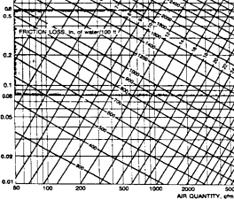

In addition to ACCA Manual J for calculating building heat/cool loads, there

is also Manual D covering air-handling and ductwork design. This is a bit

more important than most people think, as ducts that are too restrictive

will greatly reduce the performance of an otherwise perfectly good HVAC

system and cause occupant discomfort complaints. Air has a certain specific

heat capacity, and if that's to be the medium to carry heat to or from a

space then one must ensure that enough of it can reach the target area per

unit time. Manual D is all about duct sizing [ahem, that's *duct* sizing]

and CFM and static pressure, a certain portion of which can be summed up in

this chart

or a slide-rule type of tool called a "ductulator". There is also a bunch

of info on how various bends, junctions, transitions and takeoffs affect

airflow and that all has to be plowed into a proper duct design.

|

|

I don't even remember where I found this graphic, another crazy tangle of

logarithmic lines that does make sense once you study it for a bit, but

it's called an "air friction chart" and

gives a lot of information in one easy-to-read place. Most residential

designs land in the rectangle bounded by .06 to .6 inches of water and maybe

up to 2000 CFM, between the slightly heavier-looking horizontal lines

that presumably indicate a sort of sweet-spot area of static pressure.

Area conversions from round to rectangular ducts are left to the user,

but I quickly figured out that my 10 x 3 inch runouts are about

equivalent to six-inch round.

Some HVAC guys are outwardly leery of re-using an existing duct system

for any changed heating/cooling plant, and encourage grinding through a full

room-by-room Manual D which can often result in recommendations to

replace a lot of ductwork. "See, the computer said so!" ... Cha-ching!

But when a system is being *downsized*, as mine was about

to be, one could easily argue that an existing set of ducts would be

completely adequate as the overall airflow would be *less*. Undersized

ducts are a common problem cause, but slightly oversized ones, especially

when contained fully within the conditioned space as mine are, can

perform perfectly well. I spent a little time angsting about whether my

old ducts would be sufficient but after firming up the capacity math

and noting that I'd be going from 1000 CFM to about 600 max at the

blower thus almost halving the flow, I knew I'd be fine with it.

My system has a slight advantage that was somewhat unusual back in the

days when it was built. A traditional forced-air heating configuration

ran the supply ducts out toward the exterior walls and tended to place

registers under windows, in an effort to combat cold air sliding down

off the crappy single panes of the time and minimize chilly drafts

that people would feel. But the old system here has the supplies toward

the inside, with the warmed air kept near the central core of the house

for its short trip to the outlets and the *returns* placed on the exterior

walls. The advantage in a better-insulated scenario is that the supply

air doesn't lose as much heat

into the surrounding basement before being delivered, and if the return

air gets chilly on its way to the furnace it doesn't matter, it's going

to get warmed up anyway. In many downsized systems with lower airflow,

minimizing heat/cool loss in transit becomes a little more significant

because the air stays in the duct longer. In systems with ducting run

through unconditioned spaces such as attics, it's much more significant

as a lot of energy can be lost even with insulated runs in good repair.

Since my basement is part of the conditioned space anyway, it matters far

less and thus my "duct loss" figure is zero.

|

At this point I had discovered that Daikin AC had a central

At this point I had discovered that Daikin AC had a central