|

In the two years following discovery of the MFD problem cause, I

fixed two more units for other people, almost grudgingly collecting a

nominal sum for the work. Not exactly the booming MFD-exchange-fixit

sideline I thought might possibly start up ... but not only did those two

other units have the exact same problem, almost everyone reporting in on the

original thread

who dug into their own units far enough found the same situation and often

managed to fix them the same way. That's rather gratifying -- i.e. just

finding out that I was right about the problem, or maybe just plain lucky,

and being able to help the community in a tangibly useful way. That's

really a better reward than a few bucks to fix more screens.

[A third local potential customer brought me the entire car one day, but

a quick look at the hairline crack all the way across the glass under the

touchpad surface told me she had a very different problem. I pointed

her toward Steve

for a replacement unit with the suggestion that the screen itself might

be able to swap between NAV and non-NAV equipped units; I don't know if

that worked out or not.]

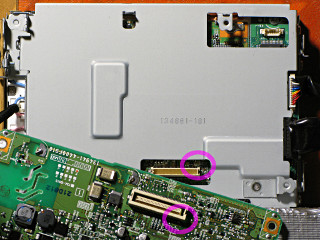

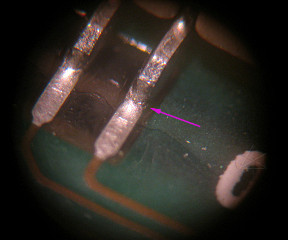

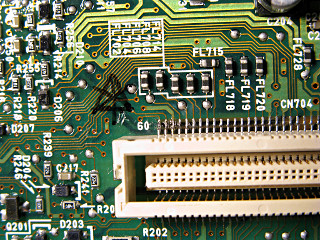

In the process of disassembling subsequent units, I noticed another aspect

of how they're are put together that could have contributed to the problem.

I took the opportunity during my second "professional" fix to try documenting

this carefully and offer a possible preventive measure that if done early

enough, could stave off the connector problem indefinitely without any

soldering.

|