There's a nice general view underneath the Kona in this video from Edmunds.

|

There are two separate pieces to the aero plastic under-covers in the

front.

The forward one had been off for some time, but now I wanted a good look

at the underside of everything forward of the battery pack.

To effect this I raised the front end about as far as I could with my

existing scissor-jacks and stands, although maybe I should have hauled

out the old red ramps to try for this...

The "oil change carpet" underneath allowed for a bit more comfort while

crawling around under there.

Both covers attach using a mix of nuts, bolts, and those annoying little

plastic expandy-pins with the plungers.

There's a nice general view underneath the Kona in this video from Edmunds. |

| Having the forward under-cover off allowed snaking my hand up through the front to disconnect the little alarm-beeper that makes noise when the car gets locked or unlocked electronically. It's the little green object near the right in the shot of the VESS box between the lights and bumper frame. It was still a bit hard to get at with the nose of the car still on, as there's a lot of other stuff in the way. It's totally invisible and inaccesible from above. | |

|

With both parts of the under-cover off, now we can see all of the motor,

suspension, and battery connections in all their shiny new glory.

The motor itself is the ribbed left half here, bolted up to the

final drive.

The extra round can on the right is the electric A/C compressor.

Even with jacking up the car a little and putting a rug down for them, I found most car-show attendees unwilling to crouch down and look under the front of the car. Instead, I can simply print this labeled graphic and tape it to the front so they can see the layout, and not have to pull off all the plastic before going to an event. [Yes, I'm still running a monochrome printer...] |

|

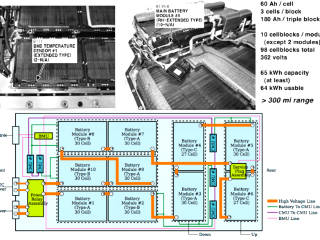

Having a look inside the battery pack would involve dropping the entire thing out of the car, which requires all kinds of heavy-duty lifting equipment, so that wasn't about to happen here. [Although people *have* accomplished such things in a driveway at home with a handful of jacks and blocks.] I found some nice bits of documentation on it in Techinfo, though, and printed up a nice architecture and fact sheet to display while at the NDEW events. I added a quick summary of how the capacity is built up, to give a viewer a better idea of just what goes into these things. There's a much more in-depth technical look at battery innards in an Electricrevs article from late 2018 when Kona sales were starting to ramp up; recommended reading for anyone who likes geeking out on such topics. A key thing to note in that is not all versions include the heater hardware. |

|

Here's what the same area looks like in models with the battery heater, according to a small shot in disassembly instructions from Techinfo. The smaller orange wire runs to a module inserted in the cooling lines to the pack, and the relays to energize it are in the pack itself. |

|

After examining all this stuff I left the covers off for another week to

have it all visible for events during National Drive Electric Week, and

part of my geek-out display was the carpet in front of the car with a sign

taped to it saying "MOTOR!" and an arrow pointing underneath.

You can't see it from above at all, too much other stuff in the way.

Those who were willing to kneel down were encouraged to do so and have

a look at this TINY LITTLE thing that could produce 200 horsepower!

I even had the front end jacked up a little to make viewing easier.

All of maybe two people actually crouched down for a look, so maybe that

was more trouble than it was worth.

A couple of days afterward I put both covers back on, because I had seen

enough under here for the moment, colder weather was on the way, and I

did want to try and keep it all cleaner and more protected.

Over the intervening winter, the community started learning some disturbing information about the Kona -- it wasn't the perfect little problem-free EV after all, at least in a few scattered instances. A recall had been issued for internal leaks in the coolant pumps in some of the cars. There were growing concerns about motor shaft alignment and reduction-gear bearings, in both the Kona and the Kia Niro. A few owners reported increasingly loud tapping noises and other symptoms as they drove, and those that took their cars in for warranty service faced a nightmare in getting the problem even acknowledged, let alone fixed. Hyundai/Kia seemed unable to determine what the problems were, if it was one generic issue or several different ones, and most repair cases endured stupidly-long waits for parts to ship from Korea while their cars languished at dealerships. It became a game of blind parts-swapping most of the time, and these are major heavy and expensive parts of the powertrain. And all of that was compounded with the arrival of the pandemic, which forced a lot of this activity to halt for several weeks. A lot of this fell into a very long thread on InsideEVs, with a surprising number of owners chiming in with "me too"s, recordings of the noise, pointers to other forum posts, and conjectures. At one point I solicited a quick survey of the affected owners to get a sense of their driving styles. Here's one problem with this new generation of production electric vehicles: they're too much fun. That is, with all the instant power they have on tap and far less relative energy penalty for using it, some people love to play! What's funny is that the Kona is already on the low end of electric vehicle performance -- single motor FWD with decidedly mediocre factory tires -- compare with dual-motor setups from Tesla and the other makers at 400 HP and up, and things can rapidly get, well, ludicrous. Tesla had not been immune to such problems either -- some of the early model S drive units developed similar rattles and needed replacement. The Kona's performance is way more than *I* personally need for getting around, so one one hand I could be smug and think gentle driving would prevent such issues from cropping up for me, but perhaps that wasn't actually true if it was an inherent design problem. Most of the respondents to my mini-poll said they weren't out thrashing their cars in any particularly vigorous way, and some drivers did seem to eventually get things fixed with motor *and/or* gearbox replacement. And possibly a dash of luck, as precise parts alignment on assembly seeemd to be a critical aspect of the design. I think the conclusion was that *some* of the drive units were just shredding themselves internally no matter what, so like with the virus, symptoms were highly random across the populace, and everyone just bumbled on with life hoping that it wouldn't happen to them and that there would eventually be a real answer. As the next Spring arrived I wanted to get back under there for a more detailed look at some things, especially after reading some of the TSBs and stories that had emerged. I wasn't about to drop motors and transmissions, but there were other things to collect information on and the under-cover had to come back off first. This time I drove the car up onto ramps, which was quite a bit easier than wrestling with pairs of jacks and stands. So our tour continues... |

|

The coolant lines run in and out of the jacket on the front of the motor. The pipes passing by underneath are refrigerant lines to and from the compressor. |

|

Both pumps wanted a close inspection, because one symptom of the internal

coolant leak is corrosion showing up on the pins of the electrical

connector.

I unbolted the brackets for both so I could move them around a little for

better visual angles -- much easier to do from below than above, although

wrenching ultimately happened from both directions.

The pump problem affected the Kona and Niro, as they use some of the same parts. For this there was an actual recall with diagnosis and fix instructions, and although the TSB for the Kona didn't mention manufacture date windows affected by it, the Kia TSB does. My vehicle's placard date fell *just* past the window which ended in January 2019, and the Hyundaiusa website didn't show anything outstanding for my VIN, but I wanted to see what they were on about and make sure there was nothing obvious to see. I could collect more geeky pictures, at any rate. |

_H* 191007