| [Note: this is not a product or kit. It is part of a strictly one-off series of analog Prius instrumentation, documented as a model for those who would want to build [and likely improve upon] the original design.] |

For some obscure reason, Toyota does not provide an engine or coolant temperature gauge visible to the driver of a Prius. However, a sensor for it is certainly installed, and coolant temp is one important input factor in many decisions made by the computers. Different functional states in the hybrid system are entered as the ICE warms up and cools down. However, knowing how warm the engine is can give the *driver* a better expectation of how the car will behave, as well as a better view into how temperature and heat loss may be affecting fuel economy. So it seems useful to add some sort of readout, and then document it in a somewhat overkill web page.

Engine temperature in the Prius [and probably most other modern cars] is read from the coolant passing a particular point in the cylinder head, via a negative-temperature-coefficient thermistor device in contact with the glycol flow. The thermistor is fed from a bias circuit with a fixed resistor of about 2500 ohms, powered by a +5V rail internally generated by the ECM for the engine. There are actually several thermistors used around the car -- one for intake-air temperature in the throttle body throat, one for outside ambient temperature hung in front of the radiator, another in the coolant-storage thermos bottle, probably a couple more related to cabin-air temp control, etc.

As thermistor temperature rises, its resistance goes down and thus the voltage read from the junction at "THW" falls as well. The problem is that the response of the thermistor is very non-linear, changing its resistance much more per degree at colder temperatures than when it is warm. Note that not only does the resistance follow a characteristic curve, its scale on the left is *logarithmic*, indicating that resistance variation is even wider than it looks at low temperatures. Adding the fixed series resistor helps flatten this out a little bit, especially through the region of real interest, but it's still not feasible to track with a straightforward gauge. The span in question is from a reasonable range of outdoor ambient up to slightly above the normal running temperature of the engine when the radiator thermostat starts opening [about 180 F or 82 C]. The standard way of dealing with this is to read the sensor voltage through an A/D converter and let the computer simply index it into a lookup table and do a little curve-fitting to determine the temperature. The car's ECM does this, and that value can then be queried and read via OBDII. A number of Prius drivers are already out there happily reading their engine temperature with a ScanGauge or CANView or similar products. However, the overall development of my particular instrumentation block has been in the analog domain so far, directly tapping certain sensor and control leads and displaying their states appropriately. The gauge cluster includes a generic 0 - 15 voltmeter, useful for monitoring not only the 12V bus but also displaying any other voltage value of interest. Therefore, the challenge is to convert the thermistor output into a linear voltage, giving a rough representation of temperature value over a range that maps reasonably well into what the meter displays. This conveniently turns out to be 0 - 10 volts to indicate 0 - 100 degrees C.

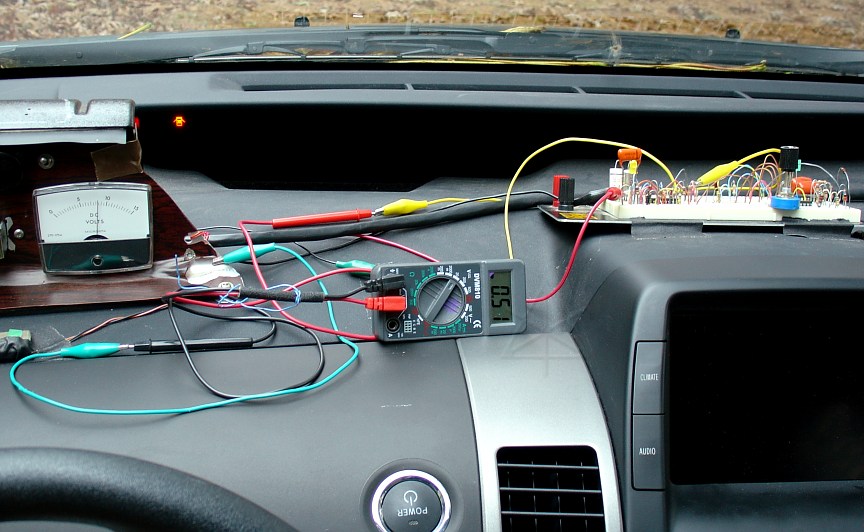

First step, of course, is to find the appropriate line. It's the THW lead, initially tapped by the traditional paper-clip jammed in next to the lug and brought up atop the dash to the "temporary" breadboard [that had been riding around in the car the entire summer, ahem].

Direct voltmeter readings could then be correlated against the ECT data read from an OBDII scan tool. This little table was made just by watching a warmup cycle and scribbling numbers and then roughly graphing it, although in the warmer weather at the time I couldn't get lower than 20 C. Then Ken@Japan was kind enough to post his "official" table: VOLT __ degree C 4.09 __ 0 3.64 __ 5 3.22 __10 2.78 __15 2.46 __20 2.18 __25 1.88 __30 1.67 __35 1.48 __40 1.31 __45 1.15 __50 1.01 __55 0.88 __60 0.77 __65 0.68 __70 0.60 __75 0.53 __80 0.47 __85 0.41 __90 0.36 __95 0.32 __100 Either way, that annoying nonlinearity is still there. Ignoring that for the time being, the logical next step was to drop a simple 10x voltage gain op-amp circuit onto the proto-board to see part of the raw thermistor output range on the meter, which would top out at 11V or so [aka 50 C or cooler] but at least display the high end of the range of interest. It would sink down to just about 5V [aka .5V at the thermistor] as the engine fully warmed up. Armed with that simple follower and the little graph above I could have easily remembered a couple of arbitrary critical points and gone on with life, but I figured it would be much nicer to follow through on the use-the-voltmeter idea and convert to degrees C somehow. Doing that would also give me greater display range, from zero C [freezing] to 100 C [when the radiator fans come on and you might want to become concerned about overheating]. I wanted to at least *try* for such a circuit before permanently building anything onto the component board behind the gauge panel. After groping around the net for thermistor-conditioning circuit examples and reading up on logarithmic amplifiers in Horowitz & Hill, I realized that I needed something like that -- something with nonlinear elements in the feedback path but customized for the voltages in question. I noodled a couple of gain structures and dug around in the junkbox stock of Zener diodes to see what I had, and figured I could obtain reasonable enough accuracy with two inflection points of gain-slope change to approximate the curve. Obviously some part of it would have to be an inverting amp, so that output voltage would increase as the thermistor voltage came down.

After some initial testing on the bench, it was back to wires-all-over-the- dash mode. I could fake the thermistor voltage input with a pot [the blue frob near the right side of the protoboard] to fine-tune the circuit response. That's how I'm getting readings here despite the car not being powered on! Then I could power up the HV system and the OBDII scanner and see how close I was getting. I realized that I could also carefully bias the thermistor input itself, and cause changes in the OBDII readings without the engine temp itself needing to rise. Here we see a nice correspondence between .5V and a little over 80 deg C, which is about right for normal steady-state running temperature.

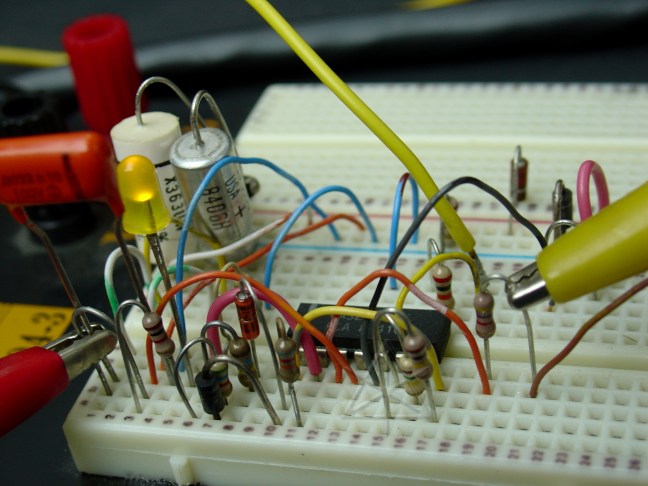

The bulk of trial-and-error happened right here, in the little nest of zener diodes and resistors. The end result? A circuit that works fairly well, described below. The best way to refine the accuracy, frankly, was to just screw around with resistor values until it worked. I have no idea what the transfer function of this thing is by now, and it's just not worth trying to do the math. Besides, the zener diodes don't exhibit sharp transitions at the inflection points -- a side effect which actually helps make the circuit's response curve much smoother and more accurate. It gets slightly weird near the 0 and 100 endpoints, but otherwise it's within about 10 degrees over the whole range. Certainly good enough to commit to a permanent circuit, considering that it's driving a cheap Rat Shack analog voltmeter.

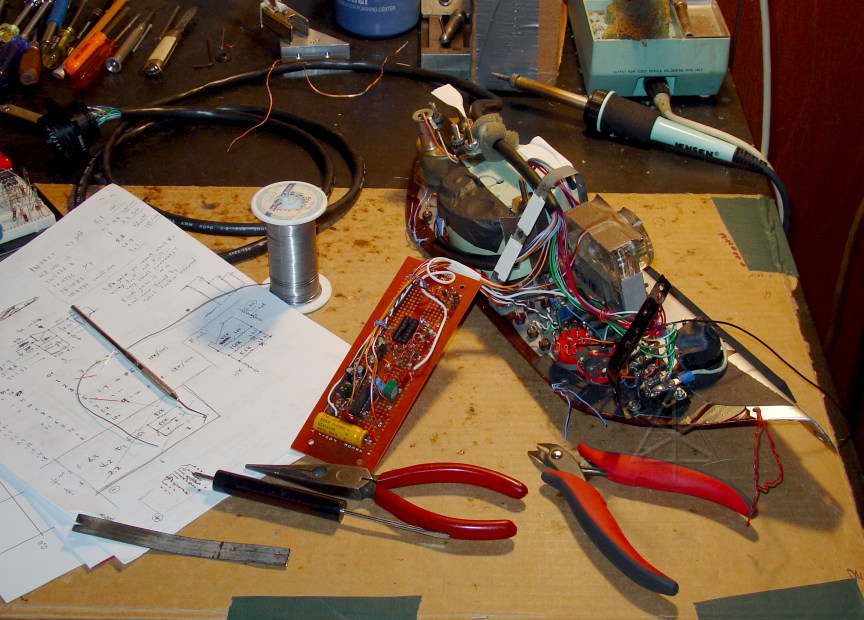

This was the last hack to go into the first round of Prius instrumentation, and it was time to add it into the gauge panel for real and button the whole thing up for the winter season. So not only did the working circuit get transferred to the little circuit board here, the wiring behind it was neatened up a bit and the proto-board taken out of the car for the moment. And the THW tap was de-paper-clipped and made permanent via the usual slit/solder attachment, with a lead through the Big Connector up to the panel. In fact, at first I tapped the wrong ECU wire [which is also white and right next to THW, dammit] and wound up reading IAT instead. I left that in for a day or two to better see the effects of the warm-air intake mod [see http://techno-fandom.org/~hobbit/cars/warmair/], and then finally moved it to THW and dressed up the harnesses behind the glovebox. This whole gauge effort is definitely a one-off prototype, since many of the parts [including the panel itself!] are reclaimed from 20-year-old projects in long-past vehicles. Reuse, recycle!

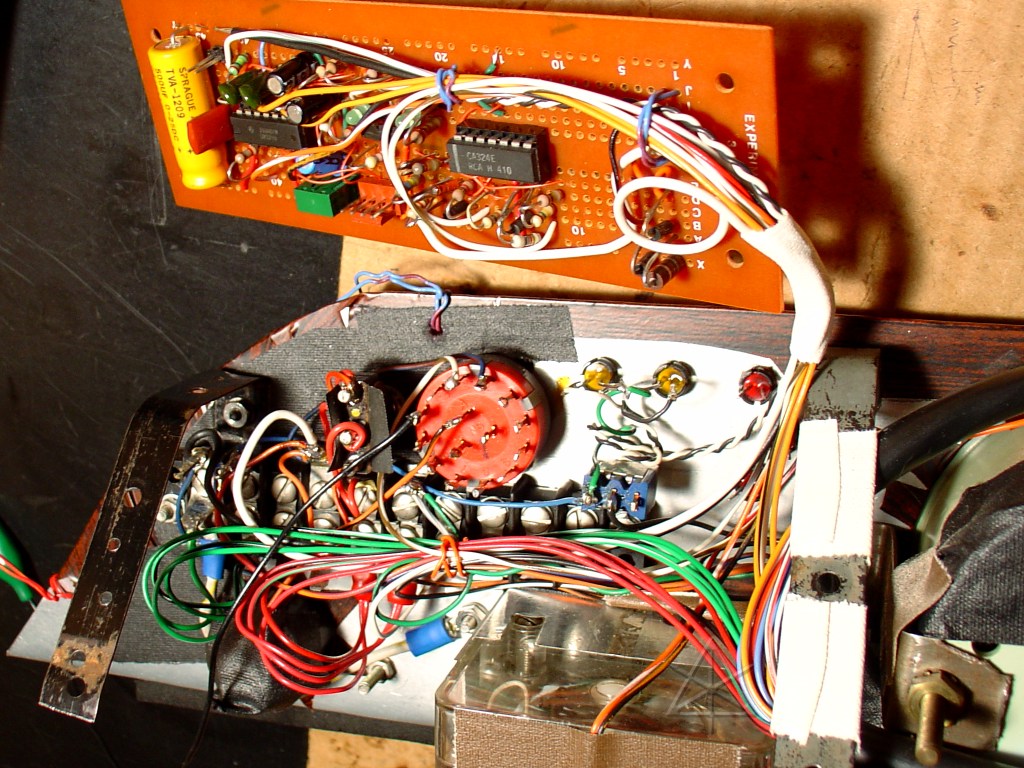

The circuit board holds the electronics to support the injector-monitor light, the current meter, the brake-pressure monitor, and now the temp gauge. It bolts onto the steel packing-strap braces on the rear of the panel. The big red rotary switch is the selector for what the voltmeter shows, and yes, it's a break-before-make type. There's still a little real estate left on the board, two unused op-amps, and more inputs to the switch, so I might come up with something else to monitor later on. Fuel injector duty cycle, perhaps? Gotta love those LM324 op-amps. Their inputs are valid to or even below the negative rail, so they're perfect for ground-referenced single-supply conversion circuits like this.

Most resistor values were determined experimentally, and results from trying to duplicate this exact circuit may vary due to resistor tolerances, zener characteristics, etc. Starting at the second op-amp and working backward, R7 and R8 yield an inverting amp with a gain of 1.5x, sufficient to take a certain range of intermediate voltage (Vi) and span an output from the negative rail to near +12V while "seesawing" it about the 5.1V reference from Z1. This provides output over the desired range, 0 - 11ish volts. It is also preferable to do the inverting stage in the second amp, to avoid bringing the thermistor tap into a "virtual ground" point which would probably have less input impedance and possibly interfere with the signal to the ECU. But even with the much higher input impedance in the + side of the first amp, a nominal protection resistor is used in case something goes awry. Vi is the "linearized" output from the thermistor, and must be constrained in such a way that the zener diodes determine appropriate transition points over its range. At high temperatures, resistance is low and delta per degree is low, so the gain of the first op-amp must be at its highest -- in this case, perhaps 8 or 9. This is its "base state" with little or no current through the zeners. As temperature heads lower, thermistor voltage rises and the difference between the amp output and its negative input begins to crest the 3.3V threshold of the first zener stage, bringing the parallel R4 into the feedback path and changing the gain toward 4 or 5. This changeover is not sharp, in fact -- it happens over a volt or more of output delta, and as temperature falls further still the circuit transitions fairly smoothly into its third gain-mode with the 5.1V zener now in play too. Final gain, when thermistor voltage is around 3.5 or 4 volts near freezing, is less than 2x. At that point it's irrelevant since the inverting amp is producing 0V and we simply accept the limitation that temperatures lower than 0 C cannot be displayed. The engine spends relatively little time at such temperatures when running anyway. One of the most fun things about this is watching the head temperature bounce upward as the stored coolant is pumped back in from the thermos bottle at startup. If the engine is prevented from starting [by shifting to Neutral or hitting the EV button], it is obvious that the recovered heat rapidly dissipates into the rest of the block. So it is actually best to let the engine start when it wants to, right after the pump cycle when the *cylinders* are maximally preheated -- emissions are likely to be lower as a result. Continued warmup will heat the rest of the block anyway. It's also somewhat scary to see just how much cabin heating robs from the engine. It's not a particularly massive block in the first place, and a car isn't exactly the most insulated living environment, so watching the ICE struggle to stay near its operating temp while running intermittently in cold weather is a good lesson in thermal efficiency. I can almost see my gas mileage leaking away as the needle falls!

_H* 051127